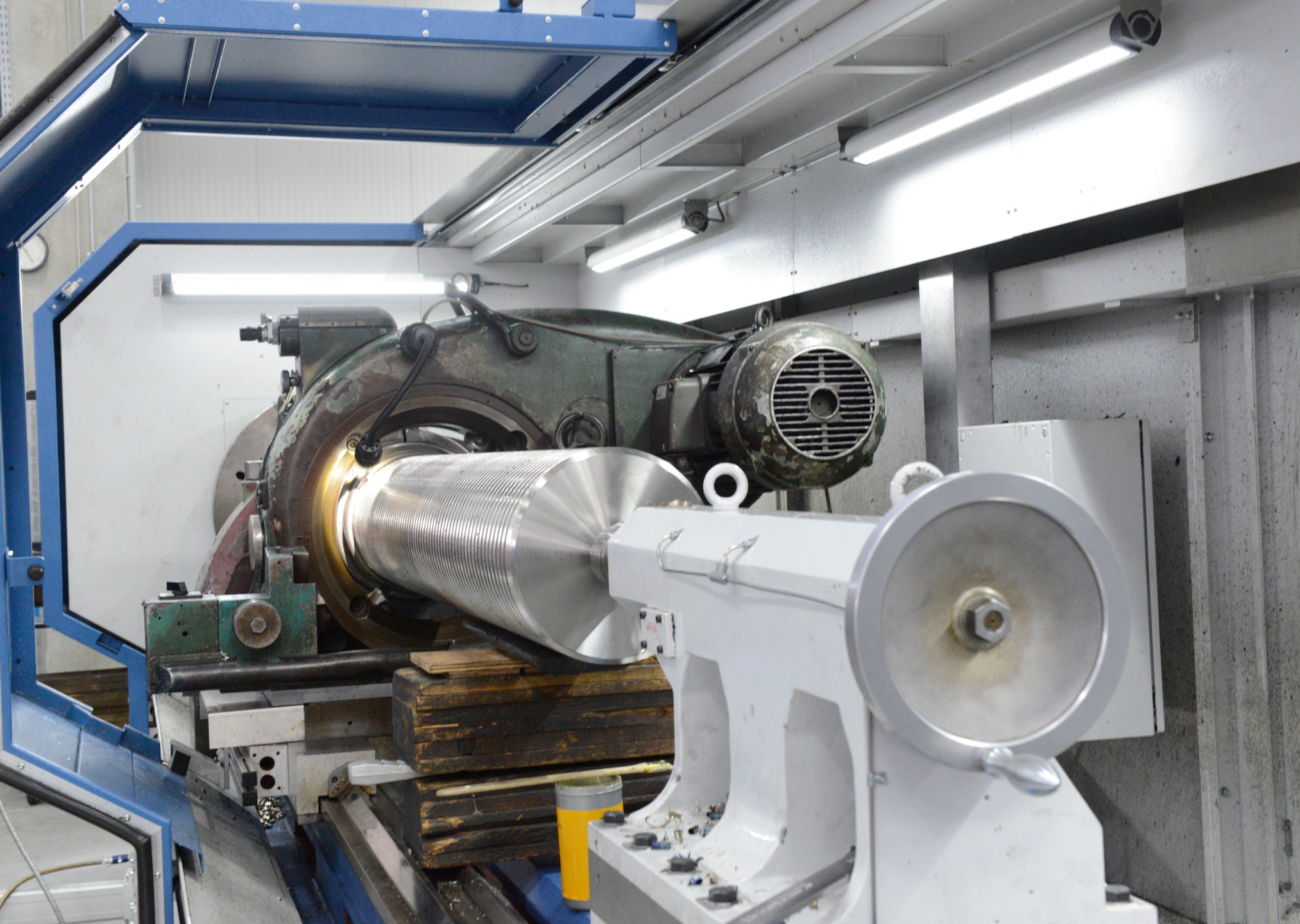

Axial stroke whirling

Axial stroke whirling is a suitable process for almost any pitch and inside diameter.

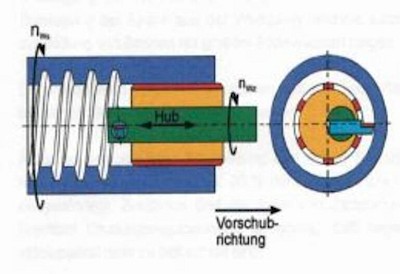

The basic idea of this process consists in substituting the rotation of the tool inclined by the pitch angle - that is required in order to produce the spiral contour - by a superimposed rotation/translation movement. The necessary stroke depends directly on the pitch. In addition, the tool is inclined by the pitch angle in the rotating and oscillating whirling mandrel.

This design allows the bearing and gear unit to be transferred from the inside diameter to the outside so that there are no space limitations restricting the sturdiness of these elements. In this case again, the support of the tool head by means of guide bars in the inside diameter ensures reliable guidance of the tool. Inside diameters from 15 mm onwards can thus be machined in virtually any lengths. Conic contours can also be produced without guiding tool head with the cutting process being limited exclusively by the maximum admissible projecting length of the whirling mandrel.