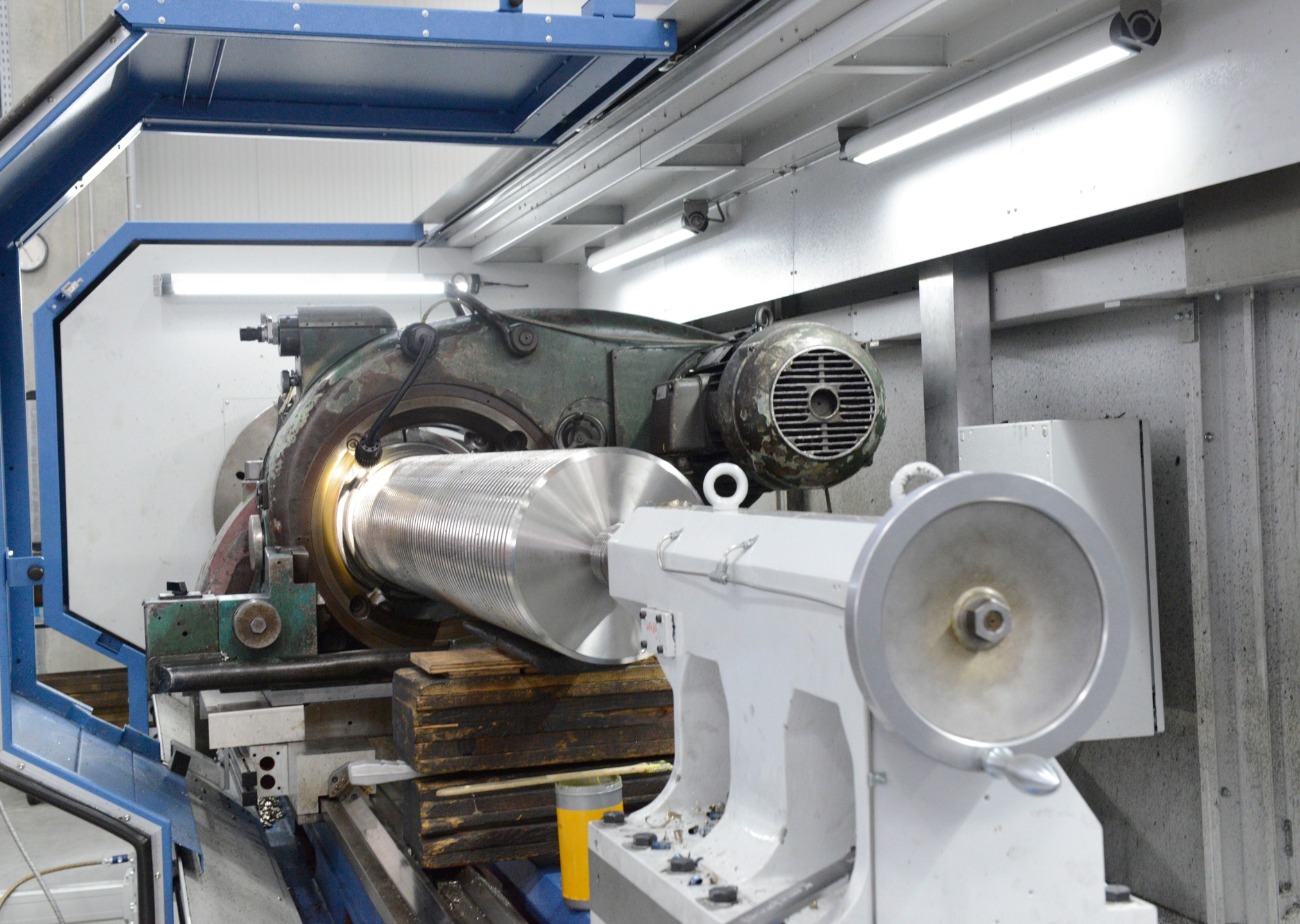

External thread whirling

In the following, the whirling process shall be described by the example of the production of a trapezoidal screw thread:

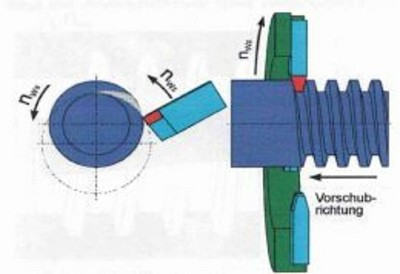

In contrast to conventional turning operations characterised by a stationary tool and a workpiece rotating at high circumferential speed, whirling involves an eccentrically rotating high-speed tool combined with a slowly rotating workpiece.

As the rotational axes of the workpiece and the tool support with the fixed tool are offset, an interrupted cutting process with discontinuous chip formation is obtained.

Both axes are inclined by the pitch angle so that in the contact point the tangent of the curve of rotation of the tool corresponds to the helix. The translatory movement required for thread cutting is produced by displacing the workpiece or the tool.

The actual feed motion required for chip removal results from the difference between the tool and workpiece speeds. Tool and workpiece can also rotate in different directions; i. e. cutting can be carried out in co-rotation or in counter-rotation.

The cutting edge penetrates into the workpiece on a circular path thus separating a chip. The workpiece than continues to turn by a certain rotation angle that is determined by the relation between tool and workpiece speed and the next chip is removed.

A defect in the form of "humps" is thus produced during the cutting process. This geometry deviation does generally not involve any negative effect as the maximum of these "humps" lies in the profile core diameter and decreases sinusoidally relative to the profile flanks. The surface contour obtained can be represented in the form of a traverse with convex connection lines. The form error with regard to the nominal tool circle is a function of turning frequency and tool and workpiece diameters as well as of the number of cutting edges.