Whirling technology

Fields of application

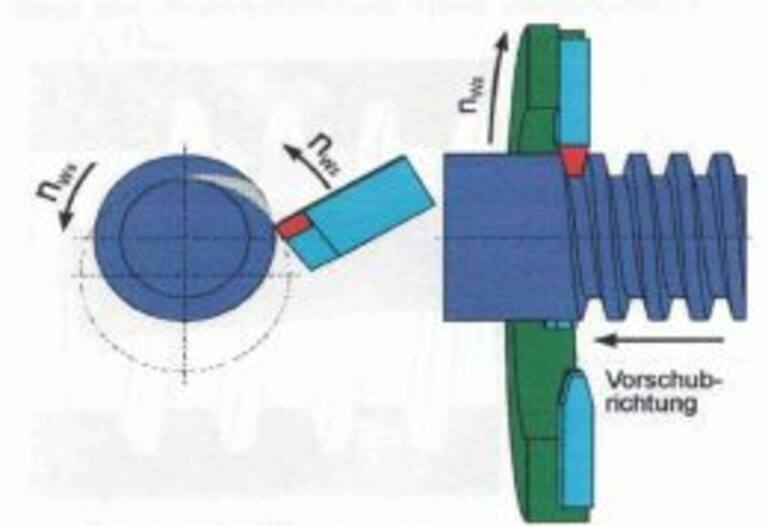

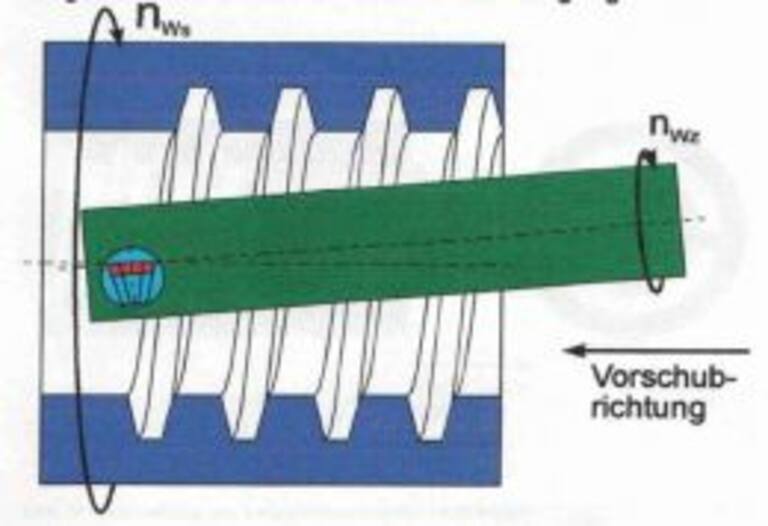

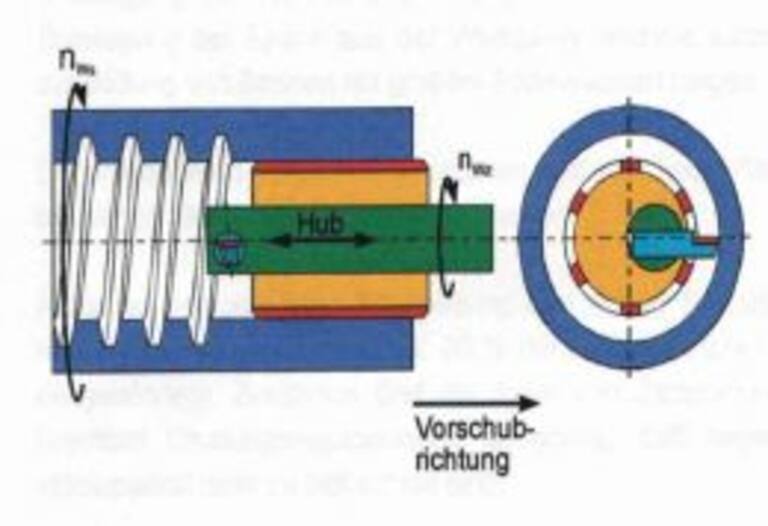

When manufacturing workpieces according to the whirling process one distinguishes between internal and external contour machining.

External contour machining is applied for workpieces of helical geometry like precision threaded spindles, worm gears, extrusion screws, screw elements and screw compressor rotors. Multiple-start threads can be obtained by subsequent processing of the individual threads or by whirling with synchronised axes. In addition, symmetric and asymmetric curve and rotational surfaces can be produced. Examples of application are lifting and main bearings, camshafts, eccentric screws, balls and polygonal profiles.

Internal whirling is applied for machining the inner surfaces of hemispherical heads, pump housings and extruder barrels and the production of internal threads for nuts of any type and heavy workpieces such us turbine housings, reactor pressure vessels and press frames.

Whirling process characteristics

Owing to the highly dynamic cutting force components involved in the specific cutting kinematics, this forming process is characterised by an extremely low workpiece heating. The dimensional deviation that is typical of turning operations due to unsteady thermal expansion in the contact area is thus considerably reduced to ensure the process-specific requirements for the production of precise workpieces. As a consequence, the workpiece temperature decreases with rising cutting speed, which results in the production of precise workpieces with exact pitch.

In contrast to the turning process, the system-inherent workpiece unbalance forces resulting during whirling are virtually reduced to zero owing to the low angular speed of the rotating workpieces. In particular with workpieces exhibiting an extremely high length/diameter ratio, a precise and stable support of the slowly rotating workpiece to compensate the passive force can be ensured.

With the interrupted cutting process a short chip is generally produced, so that the risk of damage to the workpiece surface by ribbon or tangled chips formed when cutting with a geometrically defined edge is avoided. At the same time, the chip removal from the machine tool is ensured even with materials that generally lead to high chip volumes during machining.

While the surface qualities obtained are very high, roughness values of Rt=2-8 µm combined with long service lives can be obtained.

Thanks to the favourable chip formation and high cutting speed, the primary processing time is reduced to approx. 20 % of the usual time involved (comparison milling/whirling of trapezoidal screw threads). In addition, the residual compressive stress introduced into the workpiece during the cutting process is so low that any negative effects on the workpiece quality can be excluded.

Whirling is generally carried out without the use of cooling lubricants, which implies that the time-consuming and cost-intensive cooling lubricant treatment and removal can in most cases be dispensed with. Only for cutting extremely tough materials, a minimum lubricant quantity is used. In this case, an air/oil mixture is applied onto the cutting edge to extend the service life of the tools.